reversed torsional testing|ISO 9649:2016 Metallic materials — Wire — Reverse torsion test : custom This practice is useful for generating fatigue life and cyclic deformation data on homogeneous materials under axial, torsional, and combined in- and out-of-phase axial .

webNOVINHA DO SHORTINHO SOCADO 56 sec. 56 sec Liberalmcz - 720p. MORENA CAVALA LAVANDO A LOUÇA DE SHORTINHO ATOLADO 10 min. 10 min Brunalolareal - 89.3k Views - 360p. Loirinha Gostosa Dançando de Shortinho Socado 78 sec. 78 sec Videos-Amadores-Tube - 1080p. A MORENINHA CASADA - REBOLANDO A RABA .

{plog:ftitle_list}

WEBVote and help me find out my best version. 19045. Milk Chocolate Franuí. 9418. Dark Chocolate Franuí.

This document specifies a method for determining the ability of metallic wire, of diameter dimension from 0,3 mm to 10,0 mm inclusive, to undergo plastic deformation during reverse torsion. This test is used to detect surface defects, as well as to assess ductility.

ISO 9649:2016 specifies a method for determining the ability of metallic wire of diameter dimension from 0,3 mm to 10,0 mm inclusive to undergo plastic deformation during reverse .ISO 9649, Wire- Reverse torsion test, specifies a method for determining the ability of metallic wire of diameter dimension from 0,3 mm to 10,0 mm inclusive to undergo plastic deformation .Metallic materials — Wire — Reverse torsion test 1 Scope This International Standard specifies a method for determining the ability of metallic wire of diameter dimension from 0,3mm to 10,0 .This test for determining the ability of metallic/steel wire of diameter dimension from 0,3 mm to 10,0 mm inclusive to undergo plastic deformation during reverse torsion. This test is used to .

This practice is useful for generating fatigue life and cyclic deformation data on homogeneous materials under axial, torsional, and combined in- and out-of-phase axial .This Standard specifies a method for determining the ability of metallic wire of diameter dimension from 0,3 mm to 10,0 mm inclusive to undergo plastic deformation during reverse torsion. This .

Standard Practice for Strain

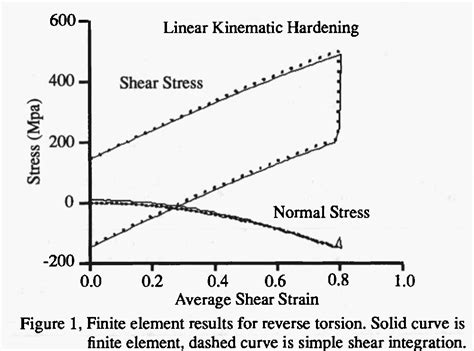

The purpose of torsion testing is to analyze the mechanical behavior of a material when subjected to twisting forces. It helps determine the material's shear modulus, shear .The thin-walled torsion specimen is examined as a test specimen for conducting reverse straining experiments. Deformation is conducted in one direction, then reversed to bring the . Experimental results for the reverse torsion of 316 stainless steel and 1100 aluminum are presented. The stainless steel results are compared with the simple shear .

In the same graphic, the test results obtained using a conventional electric servohydraulic multiaxial fatigue-testing machine are also represented (reference, Figure 10), where PP denotes push–pull, RT denotes reversed .Question Question 4 A R. R. Moore test specimen is made of steel having ultimate tensile strength of 117 ksi. Estimate the 103-cycle fatigue strength for reversed torsional loading in ksi. L A Moving to another question will save this response. Question 5 AR. R. Moore test specimen is made of steel having ultimate tensile strength of 177 ksi.C l = Load factor. The strength values obtained from the S-N (Wohler plot) result from a reversed bending load as the specimen is rotated. In the rotating-bending testing every element in the specimen diameter surface is subjected to a bend in one direction and then the other, with only a small region on the outer surface being subjected to the maximum stress level. In the reversed torsion test with P i = 0 at 0.7%, the specimen did not reach to the failure over than 170,000 cycles and the test was interrupted at the cycle. The test result shows that the failure life N f is reduced in the circle (non-proportional loading) test comparison with the push–pull and the reversed torsion (proportional loading .

The Torsion Testing Machine is a compact machine, ideal for classroom demonstrations and for safe use by small groups of students. Its frame is a rigid, precision- . • Reversed torsion tests to demonstrate the Bauschinger eff ect and the eff ects of residual body and textural

ASTM A938: Standard Test Method for Torsion Testing of Wire: Specifies the torsion testing method for wire, particularly to examine its ductility and surface defects. ASTM E2207: Standard Practice for Strain-Controlled Axial-Torsional Fatigue Testing with Thin-Walled Tubular Specimens: Provides the practice for axial-torsional fatigue testing .This document specifies a method for determining the ability of metallic wire, of diameter dimension from 0,3 mm to 10,0 mm inclusive, to undergo plastic deformation during reverse torsion. This test is used to detect surface defects, as well as to assess ductility.VoL 4, No. Æ 1993 Reverse Torsion Testing for Material Modeling presented for the stres strais distribution inn th e gauge regio ann d the macroscopic respons oe f the specimen. Even though the stresse wers e not uniform throughou tht e gaug e sectio thn e macroscopic respons oef the specimen was close t o that which would be predicted assumin .In the same graphic, the test results obtained using a conventional electric servohydraulic multiaxial fatigue-testing machine are also represented (reference, Figure 10), where PP denotes push–pull, RT denotes reversed torsion, and CI denotes circle loading, in which axial and torsional strains had a 90° phase difference. Failure life was .

Torsion testing is a type of mechanical testing that evaluates the properties of materials or devices while under stress from angular displacement. Torsion testing can be split into two distinct categories: testing raw materials like metal wires or plastic tubing to determine properties such as shear strength and modulus, or functional testing .The aim was to compare cyclic fatigue, torsional failure, and flexural resistance of NiTi endodontic files: Hyflex CM (HYF), Genius files (GEN), WaveOne Gold (WOG), and ProTaper Universal (PTU). Materials and Methods: Fifteen files of each brand were used in cyclic fatigue test and other fifteen files for flexural test and torsional failure test.

Engineering; Mechanical Engineering; Mechanical Engineering questions and answers; Estimate the 103-cycle fatigue strength for reversed torsional loading for a standard R. R. Moore test specimen made of steel having Brinell hardness of 397.torsional fatigue test, phasing is defined as the phase angle, φ, between the axial strain waveform and the shear strain wave- . sinusoidal. 3.2.4.1 in-phase axial-torsional fatigue test—for completely-reversed axial and shear strain waveforms, if the maximum value of the axial strain waveform occurs at the same time as that of the shear .A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is used to measure various mechanical properties of materials, including their modulus of rigidity, shear stress, .For the case of fully reversed bending and fully reversed torsion, the Findley material parameter k is described by Eq. (4.39) and is evaluated by the cycle dependent fatigue resistances ∆σ R,N .

Understanding Torsion TestingIn the field of mechanics and materials science, torsion testing is a crucial method for assessing the strength and behavior of materials under twisting forces. This comprehensive guide will provide an in-depth understanding of torsional testing, the machines used, and their applications in evaluating the performance and reliability .

Find step-by-step Engineering solutions and your answer to the following textbook question: Estimate the reversed torsional loading endurance limit and also the ^3$ -cycle fatigue strength for standard R. R. Moore test specimens made of steels having Brinell hardnesses of 100, 300, and 500..Question: 2- (a) Estimate reversed torsional loading endurance limit and also the 103-cycle fatigue strength for standard R.R. More test specimens made of steels having Brinell hardnesses of 100, 300, and 500.

Fully-reversed torsional fatigue tests were performed using ultrasonic torsional fatigue testing equipment and a servo-hydraulic testing machine. Cycling frequency in ultrasonic tests is about 19 kHz. The vibration of one specimen's end is used to control cyclic loading, which means that the twist amplitudes are kept constant during ultrasonic .ISO 9649:2016 - Wire — Reverse torsion test; IEC 888 Zinc Coated Steel Wires; ISO 7800 Torsion Testing Wire. Why does proper torque sensor selection matter to your torsion test application? The torque sensor is the heart of torque testing machines. It is the component that senses the torsional strength underwent by the device under test (DUT).

The torsional guided wave magnetostrictive transducer (MsT) based on the reversed Wiedemann effect has received much attention because of its high energy conversion efficiency and easy .

Reversed-Torsion-Type Crush Energy Absorption Structure and Its Inexpensive Partial-Heating Torsion Manufacturing Method Based on Origami Engineering Zhao Xilu, . The crush test is performed using an AG-X/R300KNG autograph tester made by Shimadzu and shown in Fig. 16(a). Cross sections at both ends of the RTO are machined so .

(a) esting achine Shape dim test specimen (mm) Fig.2. Testing achine test im push -pull revers torsion. 2 Push-pull and reversed torsion tests using cylinder specimen In t io res multiaxial fatigu te in push-pull an versed maxto ests of holl cylinde pecim SUS316NG (rolle stainle steel nucl ) [6] esented.A testing machine is designed and developed in such a way as to be capable of exerting simultaneous cyclic bending and twisting moments, such moments being uniformly distributed along the entire gage length of the test specimen. The ratio of bending to twisting moments can be adjusted within the range 0 to 0.5, the angular deflection of specimen being controlled in . The testing of metals to large strain using thin-walled tubular spev mens in torsion has been gaining in popularity in recent years. This pop larity has in large part stemmed from the predictions of the stress response to simple shear. This deformation mode has been shown to be able to discriminate between various material models, particularly the manner in which they .Torsion tests were performed on circular cylindrical bars to obtain torque-twist curves (the torsional shear stress vs torsional shear strain plots). The 0.2% offset yield shear strength, k, were estimated from these curves. The bars were twisted well into their plastic regions, and as the elastic/plastic torsion continued, the torques

Torsional fatigue and torsional shear testing is conducted with a variety of test machines in the laboratory. Fully reversed torque through 20K lbf/inand unidirectional torque through 1,000K lbf/in testing can be conducted typically to 3 Hz. In addition, our test temperature range is from –65 °F through 1200 °F in a laboratory air environment.

Reverse Torsion Testing for Material Modeling

web(Supports wildcard *) . Tags. Copyright? +-pokemon 566821 ? +-pokemon sv 18999 ? +-spider-man (series) 24829 Character? +-nemona (pokemon) 2347 ? +-she-venom 1251 .

reversed torsional testing|ISO 9649:2016 Metallic materials — Wire — Reverse torsion test